In the water supply and drainage treatment process, Dissolved air flotation (DAF )is the most effective method for removing the suspended matter close to the water density.

it is widely applied in water supply and drainage works below:

1. To remove algae or reduce turbidity in waterworks based lake water as its water sources.

2. Such industrial waste water treatment projects as petrochemical, textile, printing and dyeing, electroplating, tanning, food industry etc

3. Recovery of useful substances from waste water like fiber in paper making

1. Effective water depth: between 400mm and 750 mm.

2. Hydraulic retention in the tank: ( 3 ~ 5 min).

3. Large treated capacity with high surface load .

4. Small footprint, light unit load, all prefabricated components assembled,no operation room, Flexible for both overhead and multi-layer assembly .

5. Low-cost for installation and maintenance, easy to clean.

6. High degree of purification, algae and other suspended solids removal rate Over 90%, concentrated sludge concentration can reach 3-5%.

7. The device uses special clever structure of air dispenser with , over 90% dissolved air under only one-fifth of other dissolved air dispenser as well as with unique superb anti-jamming ability compared to other similar products

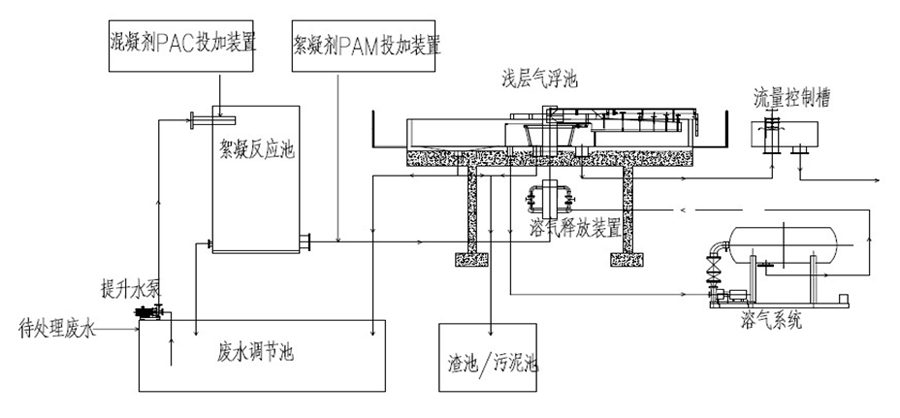

It is an compact cylindrical shallow pool which Includes the pool body, rotating water distribution mechanism, dissolved air release mechanism, rotating rack, water collection mechanism, skimming mechanism, dissolved air system, back flow water pipes and electric control cabinet etc. Its water inlet and outlet as well as sludge outlet pot are all configured in the rotating area of the equipment. The water distribution and collecting mechanism, the dissolved air release mechanism are closely connected together by rotating around the center pool rack . We provide the whole complete sets of equipment assembly and control system by setting both centralized and decentralized control to achieve the best operation characteristics.

Our superb DAF water purification technology can make the air maximize melting into the water to strive to be in a saturated state under some pressure , and then the formation of pressure dissolved water will release via pressure-reduce valve to generate abundant fine micro bubbles which will absorb floating flocculation solid in the water , the suspend solid will then float on the surface together with the bubbles to form scum which will be scrapped by skimming mechanism thus to purify the water.

I developed the ultra-efficient shallow air flotation device, is an advanced rapid air float system, in the traditional theory of air flotation, but also the successful use of the "shallow theory" and "zero speed" principle, through careful design , Set flocculation, flotation, skimming, sedimentation, scraper as a whole, is a water purification treatment of efficient equipment.

Our developed new superb efficiency shallow DAF system is an advanced quick-speed flotation system with all flocculation , flotation, skimming , mud scrapping together under successful use of the "shallow theory" and the "principle of zero speed" to gain high efficiency.

| Model | Pool DN (m) |

Flow Volume (m3/h) |

Drive Power (kw) |

Skimmer Power (kw) |

Run Load (t) |

Water Pump power (kw) |

Reaction Diameter | |

|---|---|---|---|---|---|---|---|---|

| Reaction Tank Size φDxH(m) |

Pipe Mixer DN(mm) |

|||||||

| RDAF40 | φ3 | 30-40 | 1.5 | 1.1 | 15 | 5.5 | φ2.1x2.9 | 200 |

| RDAF60 | φ4 | 50-60 | 1.5 | 1.1 | 17 | 7.5 | φ2.1x2.9 | 250 |

| RDAF80 | φ5 | 70-80 | 1.5 | 1.1 | 21 | 11 | φ2.1x2.9 | 300 |

| RDAF120 | φ6 | 100-120 | 2.2 | 1.1 | 28 | 15 | φ2.1x2.9 | 300 |

| RDAF150 | φ7 | 150 | 2.2 | 1.1 | 37 | 22 | φ2.4x3.0 | 300 |

| RDAF200 | φ8 | 200 | 2.2 | 1.5 | 42 | 22 | φ2.4x4.0 | 400 |

| RDAF250 | φ9 | 250 | 2.2 | 1.5 | 46 | 22 | φ2.4x4.9 | 400 |

| RDAF300 | φ10 | 300 | 3 | 1.5 | 57 | 30 | φ2.4x5.5 | 450 |

| RDAF400 | φ11 | 400 | 3 | 1.5 | 68 | 37 | 2-φ2.4x4.0 | 500 |

| RDAF500 | φ12 | 500 | 3 | 2.2 | 81 | 45 | 2-φ2.4x4.9 | 600 |

| RDAF600 | φ13 | 600 | 3 | 2.2 | 93 | 45 | 2-φ2.4x5.5 | 600 |

| RDAF700 | φ14 | 700 | 3 | 2.2 | 99 | 55 | 2-φ2.4x5.5 | 700 |

Remark: The back-flow ratio R=30%,Hydraulic surface load:q=6~8m3/m2.h, all subject to our final confirmation

WeChat

WeChat